Answer 2:

Hi Neil (@neilca),

Many thanks for investing in the Radical 00137, a car known to me, and thanks for your question , apologies to come back to basic questions but I have to understand more detail to help us get to the issue , I’m sure we can make your adjustable pushrods work , let’s find a way.

I would like to start with qualifying your findings ,

Is the car still in original spec , I.e. the standard Koni 2812 dampers ?

What rate and free length are the springs ?

Some simple photographs would help me grasp where we are with some parts.

When you ask ‘ run out of travel ‘ is that bump travel ?

Are tyre pressures set in ‘ on track ‘ condition Circa 28 psi ?

please define dialed in ;

What ride height were you working to ?

And where were you measuring it to ?

What corner weight targets were you working to / achieved ?

Does the suspension still have droop travel when jacked up ?

On track , with correct springs , front suspension will only use 10-15mm of travel at most circuits

I’m sure with a little feedback and validation we can find a good way forward

Kind Regards

Phil Abbott

Response from Neil:

Hi Phil,

The car is in the original configuration with the Koni’s. I have the original owners manual and used the setup numbers in the manual, so ride height at the front bulkhead is 65mm and at the rear bulkhead 70mm. The front springs are 7 inch 300#, rears 8″ 500#.

I weigh 122 Kg so I imagine I am outside your design parameter. When the corner weights were set with the fronts being equal at about 220# I had very little bump travel. With the stock push rods, the stagger in the front is about 30# and I have plenty of travel. Seems the limiting factor is the rocker on the right side hits the frame/sheetmetal before the bump stop on the shock.

Tire pressure I run is 14 psi cold, I have not checked them hot off the track.

I am not trying to solve a problem with this question, but increasing my knowledge of the suspension. I am a retired engineer and just have to know how everything works, it’s my nature. Your suspension design with the push rods and Nik bar have been the subject of many late night discussions with my racing buddies, yes adult beverages are usually involved. Brilliant stuff, difficult to grasp.

Response 2 from Phil:

Hi Neil(@neilca),

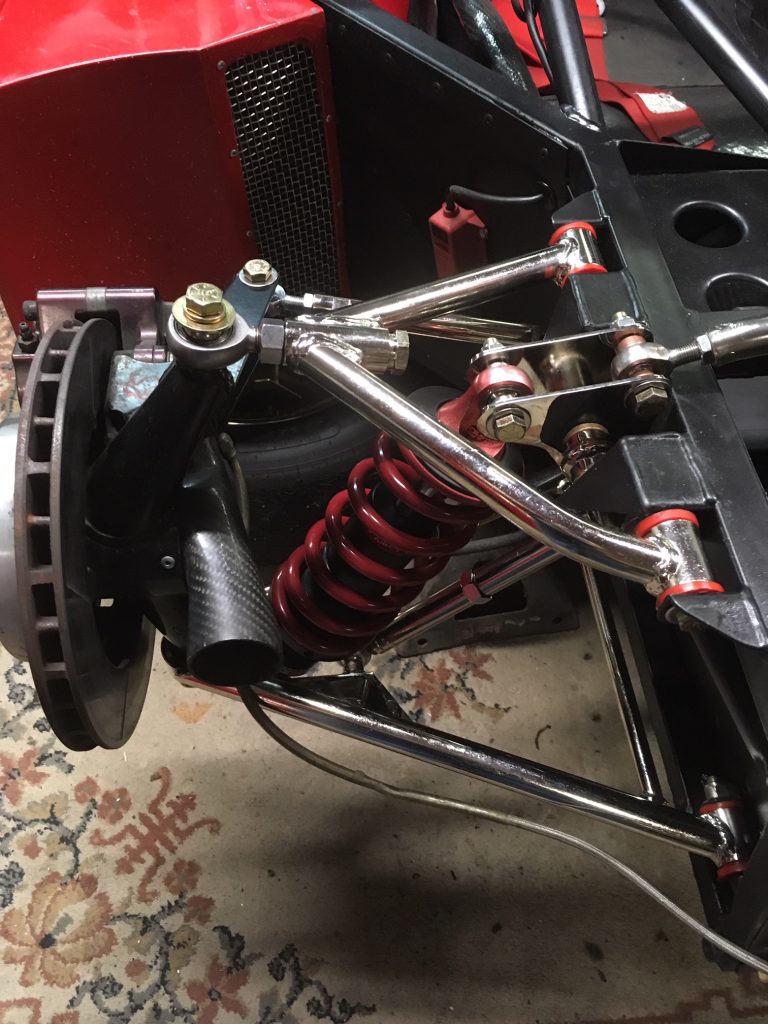

Thanks for photos, Charley kindly also sent similar from another car from that era (See attached). I think we need more beer for the debate!

In this process, we are creating a language and system of mutual understanding, so apologies if this is long winded, in person, it wouldn’t be one beers worth of time 🙄

But, based on these photos and past experience, and without the need or opportunity to measure fine details, I don’t think there is too much adrift on your car, I feel it maybe production tolerance on fabricated parts. I think the important dimensions are ok, so far. I think your adjustable push rods will help. So, let’s try cure the initial question ‘you run out of bump travel ( drivers front ? ), when setting up on flat patch‘… I think that was the main issue?

For completeness, based on the fact that weight transfer when setting up is diagonal, we should really also have a close look at the rear, before making an opinion. If we have an imbalance in rear ride height it can transfer load a front corner excessively.

Would it be possible to have similar corner pictures of the rear? Showing spring position and droop, etc., and weight numbers you see from set up scales.

I will detail our usual chassis set up process, so we are aligned in understanding.

Set scales up, using spirit level on each scale individually, then jointly north / south and east /west so that in all directions including diagonally whole platform is level – very important!

You can always check how good your set up is by once car is measured, turn car around – the numbers should be same on each corner, if not, floor is not flat.

Put Car onto patch, with driver or equivalent weight in seat distributed as driver.

Set tyre pressures, disconnect anti roll bars / Nik links, dampers to low setting, spring installed length even.

Before we Set ride heights. (With this car, with weight off car, you should try pre load in front springs turn platforms up to just contact springs, then turn platforms to two full turns of preload).

Try to leave front springs as even as possible, try to adjust corner weights from rear spring adjustment.

This is where your adjustable push rods should help, set them same length as standard ones to start with.

When adjusting corner weights. You will always have driver’s side heavier due to seating position, try to also have drivers side rear also similar amount heavy, so that diagonal weights are similar. When finished corner weights and ride heights, refit Nik link and rear anti roll bar, so that bolt just slides through without load, with driver / weight still seated.

Photos along the way would help further advice as well as others interested in this process.

Regarding the tyres, just check corner weights at a known higher number than your cold pressure, say 24psi, so that we have a constant to put in our equation.

The manufacturer will have a hot pressure recommendation, try to be close to it, paddock talk can be misleading.

As a side note, during our continued development and 25 years of tyre testing, a tyre designer friend told me – the only friend a tyre has – Is the air inside it – everything else tries to destroy it! He designed a ‘spring rate‘ in the tyre that includes the pressure, so when you vary from the design, you are changing the spring rate of the only contact you have with the ground, also that change may not be in harmony with initial suspension design and ride frequencies, so please check manufacturer recommendations.

Then if you want to experiment, alter the pressures while you are on the set up Floor, and discover the lower critical point where changes happen. Front / rear and diagonal, let one corner tyre down and see result ? It’s all data to use.

Hope you are ok with the process,

Kind Regards

Phil

The following pictures of RMS 0137 is from Neil’s car and the pictures of RMS 0108 are for comparison

The car is in the original configuration with the Koni’s. I have the original owners manual and used the setup numbers in the manual, so ride height at the front bulkhead is 65mm and at the rear bulkhead 70mm. The front springs are 7 inch 300#, rears 8″ 500#.

I weigh 122 Kg so I imagine I am outside your design parameter. When the corner weights were set with the fronts being equal at about 220# I had very little bump travel. With the stock push rods, the stagger in the front is about 30# and I have plenty of travel. Seems the limiting factor is the rocker on the right side hits the frame/sheetmetal before the bump stop on the shock.

Tire pressure I run is 14 psi cold, I have not checked them hot off the track.

I am not trying to solve a problem with this question, but increasing my knowledge of the suspension. I am a retired engineer and just have to know how everything works, it’s my nature. Your suspension design with the push rods and Nik bar have been the subject of many late night discussions with my racing buddies, yes adult beverages are usually involved. Brilliant stuff, difficult to grasp.

I will have to get with Charlie about posting pictures.