SR3 Gear Change Actuator Bearing Removal

Hi All,

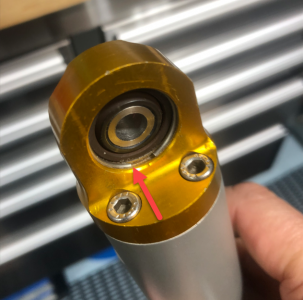

Just doing some maintenance on my SR3 and wondered if there was a trick to removing this 'retaining ring' on the gear-change actuator? I can't find anything that will get behind the wire or get under the end of it...

It looks like there's an o-ring on the other side, and mine is cracked/perished. Any idea what this o-ring is meant to do?

Any help appreciated...

Hi Rod,

Seems Radical have designed these to be non serviceable!

We take a very small ball ended Dremel type bit and machine a small cut out into the anodised metal section, next to the clip this would allow you to then get a pick behind it to remove the clip. Much like you would with a piston clip. You may end catching the clip as well so worth trying to source a replacement somewhere.

No sure on the O-Ring, I can only assume to keep the dirt out? Or act as a dampener?

@rlm-dan ... Thanks Dan. I was actually thinking about doing that exact 'hack' last weekend when I spent about 20 minutes trying to get something sharp under the end of the clip. (started with a jewelers screwdriver and then ended up trying with my sharpest scriber)

I'll get the Dremel into action and see how ugly I can make the nice anodised finish.. 🤣

Ok.. its' me here again!... I took the Dremel to the gear change actuator and managed to make that work so I could get the wire retaining clip out...

Then I've struck another issue... I can't get the spherical bearing out of the anodized housing.. nor can I get the steel bushing out of the centre of the spherical bearing...

Should the bushing push out of the bearing?... and then the spherical bearing push out of the housing?... that seems to me to make sense of how it was designed.

Not sure why I can't move either of them... and yes.. I've already given them a decent hit with a brass drift and a fairly large hammer...

... starting to wonder why I'm doing this 'preventative maintenance'!!

Any insights from those that have done this before??

Hi Rod. I have never serviced my actuator, and one option would be to replace the entire unit if it is giving you trouble. With steel roller and spherical bearings that are held in place with an interference fit, I will heat the housing to swell it to remove and insert the bearings. A propane torch could be used, but a heat gun is a better choice for this application. Sometimes it is helpful to also freeze the bearing before installation. If you do that, then probably best to first remove the aluminum housing from the actuator body.

Using a drift and brute force often scratches/scores the housing.

Hi Rod @rjbender you likely already know this but that gold anodized end of the actuator can be replaced (including the bearing) without replacing the entire actuator. I would think your local dealer can get you one, but if want to go that way and your local dealer can't get one for you , I can pick one up and ship it to you.

@charleyhradicalsportscarregistry-com

Thanks Charley - I'm actually really only taking the opportunity to do some 'preventative maintenance' while I'm preparing to rebuild my car after a pretty big shunt. There's no major problem apart from what looks like a perished o-ring under the head of the steel bushing (...and I'm not even sure what role that plays).

I'll stick it in my hydraulic press and try to 'gently push' the spherical bearing and bush apart. I'll share here what I discover...

I really appreciate your offer to help with arranging delivery of a new actuator end if needed... which will probably mean I have damaged something in my press and will be wishing I had never bothered to try and pull it apart in the first place! 😆