Compressor running often, checking for leaks

When I power up the SR3 the compressor runs for about 30-45 seconds and shuts off but then fires buck up after 30 seconds and runs for 5 or so seconds. I’m suspecting a leak and would like to investigate. Where would you start? I thought about starting with the valve block but couldn’t figure out how to get the air lines off or how the valve block is attached(looks like underneath). Thanks for any help.

I just went through this earlier this year. The biggest offender is usually the gear change solenoid block. You can remove it, and gently tighten the micro screws on the individual solenoids inside the block. There is a nice writeup here on the registry. I will try to dig up the link.

Funny side story, I fixed mine earlier this year and now my system holds air for 3-4 DAYS after a single 45 second charge. I was so used to the system bleeding down that I figured the system was broken and tracked a non-issue for 36 hours only to find out my compressor was working just fine.

Ok I’ll check that, how do you get the block out? It appears I have to take the diffuser off and unscrew it from the bottom. Also how do the air lines pop off? They look like a quick disconnect fitting but I haven’t seen this variety before.

Thx much,

Ben

Posted by: @cirrusdriver

Ok I’ll check that, how do you get the block out? It appears I have to take the diffuser off and unscrew it from the bottom. Also how do the air lines pop off? They look like a quick disconnect fitting but I haven’t seen this variety before.

Thx much,

Ben

First, if you are a Cirrus driver, that is cool. I am a 182 driver.

Second, if you are limber, you can come at it from the top. The block is just behind the driver's seat. Mine was attached by two zip ties. There is one electrical connector that needs to be disconnected and then the 4 medical grade pneumatic connectors. To get the pneumatic connectors off you simply push the entire hose in, then hold the lock collar down and pull the hose back out.

Once the block is out of the car getting it open may be tough. There is usually some silicone holding the case together. After you remove the 4 allen screws from the bottom of the case, lightly drag an Exacto blade around the seal a few times before trying to pull the housing apart.

You may also need to check the fuse, we had a similar situation and it was caused by the fuse going bad.

Radical New York, Servicing The North East

631-974-4379

www.GroupARacingTeam.com

Hey great to chat with a fellow aviation buff and car guy. I have a lot of time instructing in most of the Cessna models.

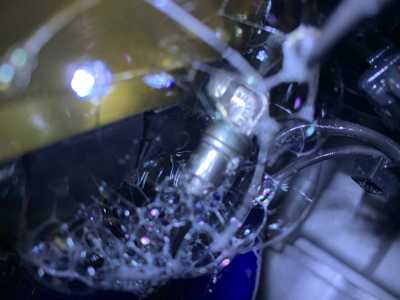

I managed to get the block out without taking the diffuser off, it was indeed held on with 2 zip ties. It was hard to get the lid off, I had to take a very small screwdriver and tap the seam to break the seal.

The great news is that she’s alive, shifts well, and held pressure for 45 minutes without kicking back on.

@cirrusdriver that is great that you also love to fly!

I am glad you were able to remedy your compressor leak! It certainly makes you feel better knowing that your compressor isn't running overtime!

I had trouble late last year with the air compressor running far more than it ever had before. Since this is a new car to us I pulled all the bodywork to see how it was put together and where all of the parts are that keep it running are.

I followed everyone's advice on testing for leaks and found that the junction block was the biggest offender by far. I fixed that and eliminated all of the other tiny leaks and don't have anymore issues with it.

When I realized there was a mechanical air gauge on the tank but can't be seen with the bodywork on I decided to splice in a mechanical gauge and add it where it can be see in the cockpit. I didn't place it for the driver to look at it while driving, but just as an external check when servicing the car.

I also emptied the water out of the air tank. I bet it was at least 1/4 full of water. This car spent most of its life in Houston where it is terribly humid 364 days a year. I don't suppose it had been drained in several years. That should help keep the shifter mechanism from getting corroded up anymore than it might already be. It was simple to do with the drain plug on the bottom. I wasn't sure which one it was but it has a recessed Allen or Torx head fitting. It has an integrated rubber seal that seems to work well.