Water Pre-Heater

Hi All,

I'm hoping someone can help with some advice or photos of their water pre-heater connections.

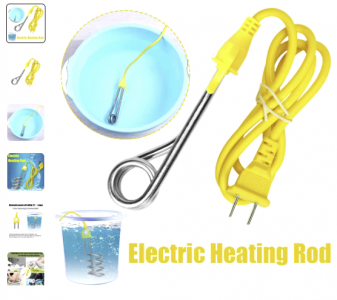

I'm building a water pre-heater that will run on 240v supply and will include an off the shelf 2kw water preheater (picture below of what I have), plus a 10amp 240v/12VDC transformer that will power a Bosch water pump (exactly the same as the pump installed in the car.. giving me a trackside spare if ever needed).

I'll build it into a suitable carry case, and run soft silicone hoses (16mm or 5/8" inside diameter) to the car.

Connection will be via Quick Connect 'Jiffy' fittings that seal when opened.

The question I'm looking for help with is where would the best place to plumb the intake to the heater and the discharge from the heater into the SR3's water circuit.

My logic at the moment is;

- Intake to the Heater; Pick up warmer water coming out of the engine block by welding a male AN fitting (with a Jiffy fitting screwed onto that) onto the swirl pot (or the aluminium line between the car and the swirl pot)

- Discharge from the Heater; Send warmer water back to the engine by welding a male AN fitting (with a Jiffy fitting screwed onto that) onto the aluminium line between car's existing water pump and the engine block

... by doing the above I'm effectively taking water from the 'hot side' (swirl pot or just before that), putting it through my off-board pump/heater arrangement, then sending it back to the 'cool side' to go back into the block for another circulation. I understand there will still be some unintended flow through the radiator and water pump in the side-pod.. but without the pump running hopefully not much.

As an added benefit I can use these ports to drain the coolant whenever needed too.(easier/cleaner than pissing coolant all over my floor when I remove the silicon hoses to drain the system.)

Does that sound right?... How do the Kenlowe units plumb in?

Any help appreciated before I start drilling holes and welding AN adaptors in place....

Hi Rod,

This is a brilliant idea that I have thought about ever since I tested my radical after purchase. I had close to four hours of track time on the day of testing plus an additional hour+ of warm-up time in between sessions. I come from a dirt midget racing background. Tolerance in those engines is extremely tight and because of that, we use a preheater for the cooling system before we ever go on the track. We used these https://www.hotheadheater.com/accessories

I plan to build a system for my car this winter but one of the things I wonder was exactly what you were asking here. With an engine hour refresh rate of 40 hours, theoretically, you could lose 10 hours due to idle warming on every rebuild cycle. I Think heating the engine in the pits with one of these could give you many more hours of race between rebuilds. Let me know what you have found out so far. I am surprised no one has responded yet. Thanks.

I was going to install this one and just have never gotten around to it.

I have contact for the US sales as well. The price I have is a bit outdated.

Jim

Hi Rod,

I have thought about doing this myself but have never gotten there.

I tried adding a heater pad to the swirl pot but its too small and cant get the energy into it.

So for now I use a hair dryer/heat gun into the side pod and through the radiator. It turns out that the radiator is as good at receiving heat as it is getting rid of it.

To pump the warm/hot coolant around I just use the onboard pump, that I unplug and plug into a 240V-12V transformer with an added timer as to not wear the pump out too much (5sec on, 30 sec off).

This works well enough getting the coolant from 20C to 60C in 1-2hrs.

For your system i think the input and outputs are in the right position and would worry about too much with a little bit of flow to the radiator.

The best thing to stop the radiator losing heat would be to stop any possible air flow.

@stewyb .. G'day Stew,

Amazing that we are sometimes on very similar development paths without knowing.. I guess that's the value if the Forum.

I tried years ago to get the water pre-heating to work with a 'heat pad' as well. It was a 250 watt pad and worked OK it just took a long time... until it shorted out and used to trip the 240 volt breaker. I think the small diameter of the swirl pot caused the heat pad element to break or come into direct contact with the aluminium swirl pot... so that idea didn't work out.

I then used a direct immersion heater I purchased off e-bay. Total cost was $10 delivered!! It was basically a 'pig tail' element with 600 watt capacity. I had to gently 'squeeze' the element in a vice to make it small enough to go into the swirl pot snout.

It worked great (15 to 60C in 40 minutes), but meant you had to take the cap off the swirl pot and insert the heater, and the pump used to have to run for about 30 seconds every 5 minutes (I like the idea of your timer by the way). If you forgot to cycle the pump the content of the swirl pot would boil and spill over... it was a little painful... hence I'm making an external water heater as described. Ultimately I will have 2 x 1000 watt water heaters and an identical 'spare' Bosch water pump' in a carry case wit some 5/8" internal diameter soft silicon hoses onto the 'dry break' connectors (-8AN size)

A good friend of mine uses a heat gun in his side pod. As you say the radiator will take on energy just as well as it will give it up!... it works great really.

Forgive me for not knowing, but what triggers the coolant pump to run with the newer ECUs? Is it ignition “on” or does the engine actually need to be running? I like the elegant solution of a proper preheater, but heating the radiator and then cycling the ignition every 10-15 minutes would be a caveman option to get some heat into the coolant (I already have the car wired to use an external 12v power supply).

I have done an external blanket and welded a bung on to the swirl pot for an immersion element. Both are slow I don't love either method as it relies on the onboard water pump and too much human intervention. Seeing this thread has me thinking about it again. Also seeing this heater unit as a middle option between DIY and the higher end options: https://hotshotengineheater.com/

Hi Walter,

That is the exact system I used for many years while racing dirt midgets. It works wonderfully! We are in the process of designing the best way to use it on radical this winter. I will post updates when I have them, but I am in the middle of a remodel on our home and it may be much closer to spring time.

Jay

That is exactly what we plan to do. The heater itself is a little bit expensive, but they last forever and work perfectly.

Jay

Posted by: @rjbender

Does that sound right?... How do the Kenlowe units plumb in?

Any help appreciated before I start drilling holes and welding AN adaptors in place....

hi Rod - did you finish this project? If so how did it go, got any pics? What are the results etc?

i'm really looking at this seriously also and i'm happy to buy a kit, just not sure at all about what fittings to get and then how to actually fix them to the coolant pipes. I think it's totally worth the expense to cut down on these engine warmup hours.

@rojid just so happens I’m installing it this weekend. I’ll get some pictures and a summary up soon.

Myself and a friend have these installed - https://p1australia.com.au/product/200-series-remote-engine-heater-kit I dont have a pic to hand but the quick disconnect reciever is installed between the body and the rear diffuser...ill get a shot when im next near the car....works exteemly well/quickly!

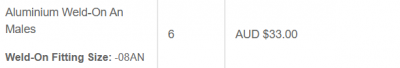

A few parts needed, and someone to weld the male AN fittings to the collant pipes, see below

ok this is working well in the garage and I will be at a chilly event this weekend to test further.

Heater from HotShot is the unit I am using. Its better in real life than the website and Ken at Apex Racing is great to work with. This is a professional looking and built piece, yet serviceable and approachable if anything were to need replacement in the future. Serviceability and being half the price of competitors are the reasons I went with it. You can build your own but I am glad I didn't in this case. Tried a blanket on, and an element in the swirl pot and its nowhere near enough.

Heater comes with jiffy-tite 3000 series female on the hoses. And mine shipped with JT male to 1/4NPT. I didn't use those because I already had lines set up on the motor before it shipped. They can probably send what you want.

CV-PL-1 from Check Valve w Fittings is the 1 inch hose barb check valve seen pictured higher in the thread. It comes with 3000 series JT male to AN6 ORB (o-ring boss). I had some AN6 ORB to AN6 male fittings and extended my lines to the rear of the car. Because of what I had around, I ended up needing a fairly odd AN6 ORB female to AN6 male adapter. There are better ways to do the plumbing if you plan everything in advance and ask vendors for the kind of fittings you want. Otherwise: ORB Female to Male

I had plenty of hose around and could have done a little better with positioning, but the coolant lines now are no worse than factory in terms of position or interference. I have aluminum pipe and Earl's EZ-beaders handy as well so shortening the long straight pipe was easy.

Testing in the garage went from 68F to to 175F in an hour. Or ambient to 81C on the dash. This is with the Heater's pump, I am not using the on board water pump at all.

Pictures (the funny square bars are an alignment rig - lots going on at the same time with the car right now)

This is version1. You can do better things with different options. This was a last minute attempt for me to get it done before my event this weekend.