wheel nut torqueing - are yall using lube?

I just heard that the center lock wheel nuts are supposed to be lubed, but cant find any mention of this in any of the download manuals. Heard some use liquid/paste, and others use dry graphite on both the bearing surface of nut to wheel and the threads. Where are the specifications or directions for this effort?

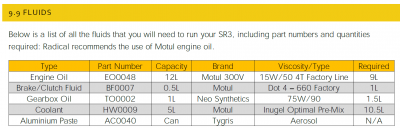

Also, within my SR3 XX Owners Manual fluids list, it calls out an aluminum paste aerosol - where the heck does that belong?

Great, I already have that. Will start using thin coating on surface and thread of wheel nuts.

@gwt561324... I'd suggest using their 'copper anti-seize' instead. Exactly the same principle in terms of how it works, but is copper based instead of aluminium. This will be better because it introduces a 'dissimilar' metal.

Our wheels and nuts are both an aluminium alloy, and using an aluminium paste isn't the best in that case. Cold welding, or 'galling' of materials is a bigger risk when using similar metals (as can be seen between our wheel nuts and rims on the tapered faces in some cases where enough lubricant hasn't been used). There is much less chance of this happening between the wheel nut and the hub thread as they are already dissimlar metals.

The one I have is a mix of graphite, copper, and aluminum and specifically mentions in the TDS using for applications where one thread is aluminum. I'll probably pick up some copper just to be safe, but the aluminum paste seems acceptable.

I understand the similar metals galling comments, but seems strange that Radical specified aluminum paste (aerosol) in Owners Manual shown above.

@gwt561324 Loctite has a 8007 can which is a copper based anti-seize will that be it ?

also I am looking for a set of wheel nuts as apares for my SR3 RSX is the radical dealer the only source for those ?

Thks

The aluminum alloy in the hubs and nuts will be harder than raw aluminum. You might also want to consider this:

On the Brinell hardness scale, tool steel has a hardness of about 700, while aluminum is 15 and copper is 35.

Copper would be worse than using raw aluminum if you were concerned about galling. Alloy's are going to change the game somewhat.

I use the same stuff Garrett is using and haven't had any issues other than it attracts a lot of dirt. A dry graphite spray on lubricant may do the job and not run into the dirt issue.

My local Radical dealer/race shop uses aerosol graphite spray on the cars they maintain. Cleaner than paste.

@trakmnky... Understanding how 'galling' occurs is a key here...

Bigger differences in the hardness LOWERS the chance of galling. That's exactly why you hear of problems with 'similar metals' and people search to use 'dissimilar metals'. That will be part of the reason that we sometimes see galling between the nut and the wheel rim (fairly common as they are similar metals), and not the nut threads and the hub (uncommon as far as I understand it, and probably due to the fact that one is steel and the other aluminium.)

I think people suggesting the use of a graphite based lubricant are probably onto a good idea. I'm currently using Copper Anti-Seize and haven't had any issues yet, but I will look into the graphite spray as it sounds like it will be less likely to trap dirt, etc.

See below for a good summary on the technical aspects;

Galling Mechanisms

The Tendency for Galling to Occur can be Reduced by Using Dissimilar and Hard Materials of Low Ductility, Lubrication, and Rougher Surfaces. Galling is an adhesion phenomenon which tends to be exaggerated with materials that exhibit a high degree of plastic behavior. It tends to occur in situations involving high loads, large apparent areas of contact, and sliding. The use of hard and dissimilar materials and a lubricant tends to reduce adhesion under these conditions. The use of materials with low ductility and rougher surfaces generally reduce the effect of plasticity on galling behavior. Both low ductility and higher roughness tend to inhibit the size of the galls that occur, which typically reduce the sensitivity of applications to the occurrence of galling.

Thus when two smooth metal surfaces are brought into contact, asperities, or high points, and not the nominal areas are in contact. Under static loading, deformation of the asperities occurs until the real contact area increases to support the load. If relative motion is then introduced, adhesive wear or galling may occur in one or both of the following ways: (1) by shearing of interface oxides protective to the base metals followed by asperity contact and welding under pressure, with the weaker of the two metals yielding; (2) by the formation of a weld junction that is stronger than either of the base metals causing wear to take place in the bulk of both materials in sliding contact.

How to Prevent Galling?

There are several points to guide for preventing galling [1].

- Lubricate if possible. Lubricant creates a layer between metallic surfaces and thus prevent galling

- Control load, speed and temperature at low levels (as low as possible)

- Avoid extremely smooth surfaces – they promote galling

- Increase contact area to reduce contact stress and wear depth

- Select alloys that show high galling stresses

- Use dissimilar alloys for the contacting materials

- Use of anti-galling coatings, such as Diamond Like Carbon, TiN, Cr, others

I called a friend of mine at Spring Mountain to ask them what they use in their shop. They said that they spray WD-40 on the threads and spindle and then wipe it clean so there is only a thin layer.

@charleyhradicalsportscarregistry-com - Thanks Charley - that would be much easier and probably cleaner too.

FWIW - I was also told by shop noted above proper wheel nut torque should be 290-300 as opposed to 260 based on their experience.

Traditional anti-seize mixed with brake dust makes a real mess. The WD-40 seems like a better plan.

I had the same question when I first bought mine, I had been using copper anti-seize which as I have now found out is wrong, It galls both the nut and wheel. I had the wheels repaired but the nuts ended up in the bin.

One big race meeting at Phillip Island (12 hour drive both ways) it rained in qualifying (Saturday morning), but then it dried out. No way could we get the right rear wheel off. Ended up having to chisel and dremel the nut off, so we missed the 1st race and that was basically the end of the weekend.

I was lucky to have 2 friends involved in the Bathurst 12 hour, one was a BMW tech working as pit crew for the Aston Martin team and the other was a good friend with the McLaren team, so I had access to both garages and also had access to pit lane using a loaned pass.

Overwhelmingly they all used the same lube, being nickel anti-seize (see pic). They all meticulously cleaned the threads and applied no lube at all. They all used the aerosol can because it's so easy to apply. You can buy this stuff on e bay. To this day I have never had a problem.

Hope that helps

Neil