That is similar to what I was thinking. I have seen racers with other types of cars use titanium shims to insulate between the pads and the rotors. Machining a set of shims would be a straight forward way of solving the problem. They could be made of carbon, as you mentioned, or titanium. Either would do a great job of insulating the pad from the pistons.

Charley

I'm back in town today, and should be able to get some measurements.

I think the .81 (21mm) rotors are too thin for our use -- I'd not want to go there, especially on a front rotor. Did you get prices on new rotors from Hi-Spec?

I can also make contact with my Wilwood contacts and see if there's a 25mm x 280 or 300mm rotor that we missed in their catalogue.

It looks like the 21mm thick rotor is the standard thickness regardless of a 280 or 300 mm diameter for the SR8 and SR3 so I’d not be worried dropping down to their width too terribly much.

If you can source or have made a 24mm/25.4mm wide disc that basically copies the carbon disc that would be the ticket. Hi-Spec has yet to respond, their bespoke rotor order form doesn’t work either. Maybe it is time to contact Wilwood.

Standard Radical pads fit in our calipers so a copied disc and standard pads would be the perfect change.

Maybe we should focus on getting a set of carbons copied. I’d gladly pack and send one of mine as a template.

Since I’m just a track rat and not racing I’ll be content with sticking to a 280mm rotor instead of upping to a 300 so I don’t have to change calipers.

"Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming 'WOW-What a Ride!'"

Ah -- I've not measured mine. You're right: if the steel rotors are 21mm from the factory, that's plenty thick.

I reached out to Wilwood with the dimensions you posted above, along with a note about a thinner rotor being ok as well. I'll let you know as soon as I get a reply.

I just got a reply from Wilwood:

the best thing you can do is comb thru my offerings and see what might work for you. I don’t have anything off the shelf, as a 10 bolt pattern is not common for us.

Let me know what you come up with (probably a hat and rotor combo that will work) and I’ll take care of you on the pricing.

https://www.wilwood.com/Rotors/RotorList1

https://www.wilwood.com/Hats/HatList

Richard, I would double check some of your information. The 260mm and 280mm Radical Rotors are both 25mm thick according to the sales literature.

Charley

Posted by: CharleyHRichard, I would double check some of your information. The 260mm and 280mm Radical Rotors are both 25mm thick according to the sales literature.

Charley

Aaarrrgghhhh!

Soooooooo......

Let’s assume that the pads on the carbon setup are what is 2mm wider (thinking about this - was surprised at the pad thickness), rotor thickness is equal and the calipers are offset accordingly. It’s all still workable.

I’m still waiting on a rotor and pad quote. Once I get that I’ll figure out who I’ll source the parts from, get them in hand and then figure out what needs to be modified.

"Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming 'WOW-What a Ride!'"

Picture heavy post.

The front and rear rotors are the same, as are the hats. Here are the dimensions of the rotors:

Hat is 22mm deep with a 4 on 108mm bolt pattern. It looks to be 8mm thick but there is some variance between the thickness at the center hole and at the lug bolt holes. Very possibly because I was having a bit of an issue getting the center hole thickness measured

Caliper and pucks:

The two spacers that keep the pads in place and the 23.25mm wide center pieces will get machined down to the correct thickness.

Pads: Looks like they're 16mm thick when new.

I have a tapered, slightly bulged wear on them

I wonder how thick new steel setup pads are?

These are the bobbins that may end up getting remade. They'll be what controls the spacing between the hat and the rotor and will center the rotor in the calipers:

So I'm going to order a set of floating 280mm rotors and pads from Spring Mountain tomorrow and start machining stuff once I get the parts in hand.

"Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming 'WOW-What a Ride!'"

Richard, with a new set of 280mm steel rotors in hand, if you can provide dimensions, I'll be able to work out if Wilwood stuff might work. The biggest problem I see with Wilwood's catalogue is a lack of floating rotors -- all the rotors in either 280 or 300 mm are bolted directly to the hat. I'm wondering if that's a showstopper...

I'm heading to Sebring this weekend and will be replacing at least the front rotors and pads afterwards, so I've got an interest well beyond theoretical. 🙂

Posted by: John ParsonsRichard, with a new set of 280mm steel rotors in hand, if you can provide dimensions, I'll be able to work out if Wilwood stuff might work. The biggest problem I see with Wilwood's catalogue is a lack of floating rotors -- all the rotors in either 280 or 300 mm are bolted directly to the hat. I'm wondering if that's a showstopper...

I'm heading to Sebring this weekend and will be replacing at least the front rotors and pads afterwards, so I've got an interest well beyond theoretical. 🙂

I doubt it's a show stopper as the base rotors are a non-floating setup (at least I see parts for them).

I'll post up dimensions when they arrive. I just (about 30 min ago) sent a request to purchase pads and rotors through SMR.

Heck, you'll have a carbon rotor in hand too - see if you can find something as close to that as possible and then find a hat with the right offset and you should be good other than this mysterious pad thickness "thing" which we'll get figured out soon enough. I'm still trying to figure out how to cut 2mm thick slices off the carbon pads for spacer/backing plates so I don't have to modify the calipers.

I wonder... If you can find a rotor that is very similar to the Radical carbon why not see if you can modify that to mount like the carbon? Just copy the 10x172 pattern into the mounting ring of the Wilwood rotor. How hard would it be for you to get your hands on some unfinished, other than braking surface, rotors? Blanks that haven't been drilled for mounting and such?

"Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming 'WOW-What a Ride!'"

I can ask my guy at Wilwood, but I will guess his response will be "no"... I'll wait to try and get that information once I get my front rotors off the car.

Parts on order from Spring Mountain and if I understood Chris correctly, parts will be shipped today. Wow.

LH FLOATING DISC 280mm E24 2.00 336.70 673.40

RH FLOATING DISC 280mm E24 2.00 336.70 673.40

P.F. Brake Pad .13 Compound (Axle set) 2.00 264.01 528.02

Shipping 57.23

Total : $ 1,932.05

That's not hateful - heck, I think it's less than a single carbon rotor.

So once I get parts in hand I'll see just what I've gotten myself into.

"Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming 'WOW-What a Ride!'"

Got a box today with rotors and one axle’s worth of pads. - box seal tape was broken and a set of pads is missing.

Sorry, no pix at the moment. I’ll post up tomorrow.

Did a test fit and I don’t think this is going to be that big of a project. The bobbins need to be cut shorter on the brake rotor side as the mounting tabs are only about half the thickness of the carbon rotors. New hardware will be needed too. The bolts are too long and a few of the nuts have cracks in the flanges. Cheap insurance to replace...

The shoulder of the bobbins also need to be either turned down along one side to clear the small step in the steel rotor or I’ll pocket the rotors where the bobbins fit against them. Either way there’s about 1mm of clearance issues.

The caliper looks like it’s going to be very close to being centered. I’ll know more after getting the bobbins and/or rotor mods set up.

Brake pads dropped right in and after pushing them (pistons) fully into the caliper the caliper slipped right over the rotor.

"Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming 'WOW-What a Ride!'"

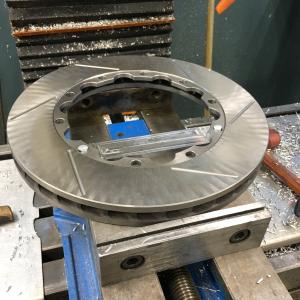

Loose bolt up of everything to see what I’m up against:

Rotor is off center by 2.5mm:

You can see the bobbins sit proud 1mm because they’re against the swept braking area:

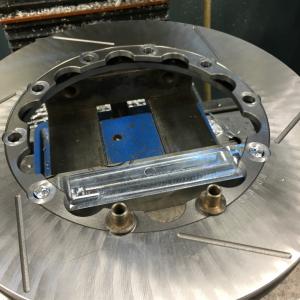

Take notice that the floating mounts are flush with the edges of the hat. The carbon rotors are on a 10 on 172mm mounting pattern while the steels are 10 on 175: Carbon mounts are 1.5mm away from the edge of the hat

while the steels are flush

The hats accommodate both diameters.

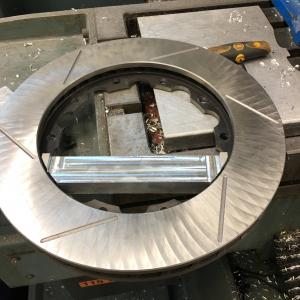

I made a jig to locate the rotors on my vice on the mill - makes repeatability nice and quick:

First round I skimmed the 1mm lip off of the swept area so the bobbins sat flush against the mounting ring:

The bobbins are too long for the rotor mounting tabs so they got worked over:

A bit (actually a lot) of Scotchbrite pad work and I have new looking mounting pieces:

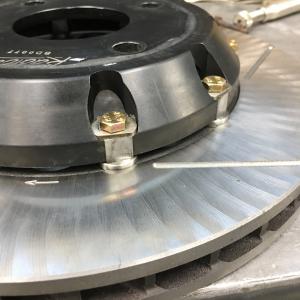

It all assembled nicely and fit right into place

but the rotor's still 1.5mm offset in the caliper:

The next logical mod was to space the caliper over 1.5mm and be done but nooooo... Of course it's not that easy. The hat ends up hitting the inside of the outer half of the caliper. So it was time to mod the rotor again and sink the bobbins into the mounting tabs 1.5mm:

Which gave me perfect alignment:

I'm not worried about removing a bit off the thickness of the rotors' mounting tabs. The forces they see are perpendicular to the mounting hardware so the load isn't going to tear or break the tabs even though they're slightly thinner.

The rear rotors, with the modded pockets and bobbins dropped right into place with perfect alignment:

So now it's wait for the mounting hardware to show, finish assembly of all four rotors and put 'em back onto the car.

I'll do a brake system flush (putting Motul 600 in), change out the engine oil and go see what this venture yields next weekend at the track.

Does anyone have or can anyone direct me to torque amounts? I need them for the bolts that hold the rear axles in place, the bolts that hold the hats in place and the caliper mounts.

One other thing I have to do is get back in touch with SMR and query what to do with the cooling lines for the rear brakes. There was a comment about redirecting the duct work off of the rotors and onto the transmission or bell housing made but I don’t recall exactly was was said.

Lastly, anyone have any suggestion on brake bedding?

"Life is not a journey to the grave with the intention of arriving safely in a pretty and well preserved body, but rather to skid in broadside, thoroughly used up, totally worn out, and loudly proclaiming 'WOW-What a Ride!'"