Some progress on the MBE ECU idle/TPS after using the Charlie/Radical info noted in the above post.

I used my voltmeter with a safety pin to access the red wire on the TPS. With ignition on and engine off, I grounded the voltmeter black and clipped the safety pin on the red. I pushed the pin through the red wire insulation and took TPS voltage readings. A tiny hole on which I will put a bit of silicone caulk when I'm all done.

To recap my primary issue, when I tried to start up the engine after a long storage, it would not start without a pretty good bit of throttle. After it warmed up, it would start and idle OK. I synched the carbs and adjusted the idle screw but I could not get it to start and idle correctly. Using the above info to adjust the TPS, I first checked to see where I was ... .39V. I adjusted the TPS to achieve about .20V (CW on the housing reduces the voltage). It was immediately better, and started and idled with no additional throttle. The idle was too high so I alternately adjusted the idle and the TPS until I had the idle and TPS (.20V) where I wanted them. Note that the TPS voltage does not change with engine off or on. Sooo ... everything is cool! Not so fast ... as it warmed up, the idle started to slow down until it would barely run and eventually stalled. I went back and forth on idle screw and TPS until it was OK again. I let it cool down and when I went to start again, the idle was waaay too high. For some reason, which hopefully someone or Mr. Radical, can help with, my idle is slowing down a lot with engine temp, to the point where the engine stalls. I also still have the problem of the engine heating up prematurely. Could this be engine friction ... it heats up and then tightens up which pulls the idle down? I've got fresh Mobil 1 4T Racing 10-40 oil.

@speedstarincdjb, Yesterday after I emailed you I reached out to one of my friends that is an expert on these early cars to get his advice. He said that he doubts that this is an ECU issue (and I agree). He said it sounds like it is either a fuel issue or an air/fuel ratio issue. He said that when cars sit for a long time like this that it is common for the throttle bodies to get gummed up and they can bind. He suggested taking them off and thoroughly cleaning them getting off any lubrication that could be causing the throttles to bind (and then reapply lubricant). When you have the throttle bodies off, inspect the rubber connector that connects the TB to the engine. When those age they can leak air through cracks, warping, or getting hard.

You likely already tried the following, but when you are balancing the TBs start at the one where the throttle cable attaches and move out from there. Set them to 6-7 CFM to start. He also suggested looking to make sure that each of the throttles is consistently moving together.

He also said that throttle cable wear, corrosion, or adjustment could be affecting how the idle is changing during warm up. This is not as likely but it is easy to check by removing the throttle cable to see if you still have the issue.

He said that it is also possible that you are not getting a good spark at one or more of the cylinders. He suggested wearing a thick glove and with the car idling (if you can get it to idle) remove the plug wire from one of the cylinders and listen for a change in engine sound. Then do the same for the other cylinders to see if you can determine if one of the cylinders is not firing. Another method I have used to check for dead cylinders is on initial start up, use a water spray bottle to spray water on each of the exhaust headers and check to see that the water is evaporating evenly (approximately). If a cylinder is dead the water wont evaporate from that cylinder. Causes for a dead cylinder could be a bad coil, bad wire, or fuel delivery.

He also suggested checking for water in your oil.

I know you have likely tried many of these things, but hopefully one of them will help.

On my recent engine swap, when I started it for the first time it was misfiring and not running long. I noticed when I connected the coil wire to the number 2 plug, there was no firm snap of the cap onto the plug terminal. I pushed down harder (which is unnecessary if the coil wire is good), but I could not get the plug wire to seat. It appeared that the contact had moved upward into the spark plug cap. I installed a new set of coil wires, and the problem was solved completely.

I don't know what is the expected life of the coil wire set, but I have not had good luck with them. If in doubt, replace.

If it starts and sounds ok when warm it is worth keeping in mind this is a slightly older car on an older version of engine management.

In my mind these always needed some throttle to start and held until they had some temperature in them and then were ok.

This would be consistent with you being able to get it to idle ok when cold but then high when warm. Might be a characteristic of the car!

@rlm-dan Thanks, Dan ... In researching what's happening I've read a lot of your posts and they are very helpful. What I've got is the opposite of what you describe. What happens is it starts and idles fine but quite high. I need the high idle when it starts because as it warms up it idles down to the point where it will hardly run and at this point it starts to backfire in the air horns (I've got the air filter housing off). After starting, it takes a few minutes until I see 57C on the dash which is when the water temp reading wakes up (checked with my pyrometer). At about 3 1/2 minutes it's at 70C and at that point it is just barely running and the backfires start in the air horns. The backfires are random and intermittent. I've got the TPS at .20 and I bumped the fuel pressure up to about 3.2bar. I couldn't find the same ecu water temp sender, which based on similar part numbers, I think is a Lucas so I bought a Bosch sensor. It made it worse ... hardly runs and backfires almost immediately. ah ha ... interesting ... so the water temp sensor makes a big difference. I unhooked it altogether and it won't start. Spring Mountain gave me another Bosch sensor to try so I'll see what that does. I also have a new BAP sensor coming to try. I don't think it's the TPS since I can read that on my voltmeter and it's good. Also new plugs, the plug wires (Magnecore) ohm out fine and snap on, had the injectors cleaned and flowed, I set the individual throttles, compression test all good, big Optima jump battery. I haven't done the coil pack but I've swapped out many over the years and it's never the coil pack. One of Charlie's friends in the business says it's rare that the ECU fails ... I hope so since the old MBE ECU's are unobtanium.

Thanks Don and apologies for not understanding correctly.

The first thing I would be looking at is your throttle body set up, one of the Radical manuals (RSX?) details on setting up the bodies. It is setting them completely closed, zeroing the TPS and then winding them open to 4%/0.18V for you. It sounds like your bodies are out of balance or not set up correctly. With the MBE on cold start it would be adding more fuel hence the high idle if the throttle is open too much. As it gets warm the ECU will be reducing the fuelling and if the throttle is too far open it will be making it run lean - hence not running and when lean it will also pop back thtough the inlet. If you cant find the instructions maybe try winding the idle screw back a turn and setting the TPS again to see if it improves.

Do you have the MBE leads? With these you can connect to the ECU and see what the sensors are reading to ensure nothing is out of spec.

If you suspect the BAP then disconnect it and let it run at default, unless you are at a high altitude as this should answer that.

I agree ECU's are very rare to fail, if it does turn out to be that don't panic - a replacement can be purchased of a later spec that will work with the wiring it is just the software/mapping that is different but the ECU can be supplied with a base map that needs tweaking - although I would also be considering a LIFE ECU and loom at that point, more expensive but offers more in terms of data logging and engine trips etc.

@rlm-dan Thanks, Dan. Your analysis makes sense, since it seems to me that the engine is running lean, at least after running a bit. I am out of town for a few weeks but I will follow your recommendations when I get back. I did set all of the idle screws and got air flows in the correct range, as well as correct TPS voltage following some directions that I found on the forum. I have; however, fussed around since then. I do not have the MBE pigtail nor any program to evaluate it. Seems that I did see one on line when I started all this and I'll look again as I know more now than I did then. Thanks, again ... very helpful. Don

Hi Don (@speedstarincdjb), How is this progressing? Any updates?

Hello Charley. I've been out of town and will be trying Dan's suggestions this week. I've also got a new temp sensor and new baro sensor to try. Don

Hello Dan and Charley, Some progress today. First thing I did was make sure that the engine would run. Without changing anything, it started and idled; however, it was a low idle, ran rough and stumbled and quit within 1 min. I checked the air flow and it was well over 7 kg/hr on the synchrometer. So .. low idle but high air flow. I changed the temp sensor from a Bosch that ohmed at about 6 ohms to another Bosch that was about 3 ohms. It made no noticeable difference. Since my air flow was high, I reduced the idle screw about 1 turn and re-set the TPS to about .20V. I did this several times lowering the idle screw and re-setting the TPS back to .20V. It would barely run, but I got the air flow to about 6. It was still lean and not happy. It would not take any throttle and would stall at the smallest throttle increase. At this point, my conclusion was that the air/fuel situation was way off even though my air flow and TPS were close to the desired range. I added about 1/2t of idle and re-set the TPS and it still wouldn't run right. Having run out of options, I decided to try lots more TPS (double, to about .40v) and started it up .... NEW WORLD! It started and ran smoothly, stable idle speed, and normal engine temps, and take throttle normally. I finally had running time to re-synch the air flows and only one was off about .5 kg/hr and set all 4 at 6.5 kg/hr at what sounded like a nice idle speed. My conclusion is that on my engine (FI 1500) and my MBE ECU, the .20v on the TPS doesn't work. On the forum, I see different numbers for the TPS setting and assume that is because of the different ECU's. So ... happy that it's running good and wondering what actual TPS number I should use; however, .40v works pretty well on this TPS.

Hi Don. I have a recent story to tell about TPS which might be relevant; I assure you I do not mean to hijack your interesting thread.

I was at the Radical Cup Sebring official test last month which means that Radical sponsors technical support for the event. Without asking, the Radical technician read my Life Data ECU and said, "this car needs a new TPS." I was puzzled because the car was running very well, however I did have a stall when engaging the clutch in the paddock, and this happened to me before on a TPS that was faulty. Several minutes later I was reviewing my track data, and indeed the throttle was bouncing between 104 and 98% on the straights. If it was working correctly, it would have held 104% while the throttle was mashed to the floor.

I think the TPS is a potentiometer. I don't much about potentiometers except that they are electrical devices that don't seem to last very long under racing conditions. Perhaps your TPS is not doing its job very well -- it is just a guess, but I have replaced as many TPS as I have swapped engines. At the very least, when you get that car on the track, pull ECU data and check the throttle output to see if it is smooth. If it is bouncing, then I would replace it.

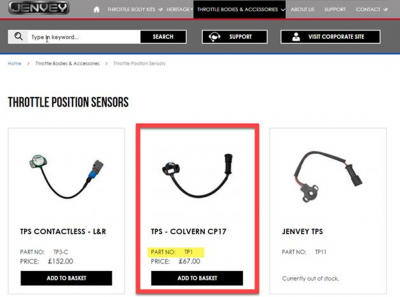

@davidf ... Great insight David. I don't know much about the TPS either.. but I do know where to buy them as I purchased a spare based on some previous comments about their reliability. Here's what I can share based on my SR3 RSX (and my XX is the same I think)

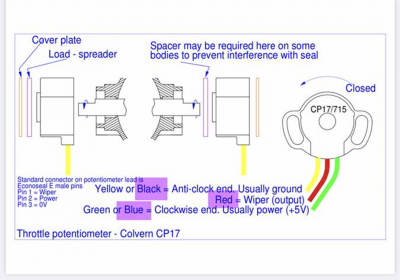

The potentiometer is supplied by Jenvey with part number TP1. My sensors have Black, Red and Blue wires…

See below the Jenvey ‘shop’ page. Note that the spec sheet also below is a Colvern CP17 (maybe these are made by Colvern and sold by Jenvey?). The spec has lots of technical details including the expected resistance range of the potentiometer, etc.

I also remember reading somewhere (EDIT - It was actually you David in a comment that was about your original TPS failure in a thread started by Dan Millsaps who had multiple failures...) that the two socket head cap screws that hold these in position once the TPS is set at ~4% only need to be done up with a very, very small torque applied, and that overtightening these is known to be one factor that causes them to fail. As I had been doing these up much tighter on my car - I decided to purchase a spare to carry in my race spares-trolley. I've never needed it , but at least now have one 'on stock'.

EDIT - here was the exact torque recommendations - tightening torque is only 1.6N.m (about 1.2ft/lb or 14in/lb)

Based on your post I will now have a look at the ECU data and see if have any 'noise' in the signal...

So I guess my suggestion for others would be not to overtighten them... and if anyone wanted a spare then you can get them direct from Jenvey/Colvern...

Thanks to Charlie, David and Rod. My TPS has some numbers on it so I'll see if I can find a new one with those numbers. Might not be like yours since my wires are Red, Yellow, and Green. Trying to get current parts to match my older stuff isn't ez. I found the exact numbers BAP sensor but I'm still not sure if I have the correct Water Temp sensor. I'm pretty sure my original part is a Lucas since the numbers on it are similar to some Lucas parts. The one I'm using now is a Bosch and seems to be working OK but it could be the reason that my TPS setting won't work at .20V. I'm thinking about a trip to the chassis dyno to see what my real A/F ratio is and maybe play with the TPS some more.

FWIW, my left-bank TPS failed at Miami-Homestead this past weekend. 2 years old, maybe 40 hours on it. I'll be replacing mine annually from now on. 😯

Glad to see that you have made some progress with this!

As Rod as mentioned it is a Jenvey sensor, the TP1. The TP11 they offer has the same linearisation and is made by Variohm, the same people that make the pressure sensors for Radical, so that could be worth trying. As said torque is also important but if you go too tight you normally notice it holding the throttle open.

With regards to water temperature the Lucas one was used originally but was unreliable so as long as the correct Bosch sensor is being used the linearisation is correct and is the right replacement.

As David F said you can often pick up on problems in the data before you notice it but this is all with the newer Life ECU's.

Rolling road test sounds like a good idea, who knows what has been changed on the car over the years!