wheel torque...talk

How on earth are you guys torquing up your wheels? Let me explain...

when we got to the track, i set my torque wrench to 360NM (as per the manual), placed some wheel chocks, and got to it. Only to find that the wheel was turning around on the surface of the pit garage - even with my mate jammed on the brake pedal.

In the end i had some team support come over with a milwaukee impact gun, and they just used the highest torque setting on it, a few seconds of 'brrrpp' and i was on my way.

So how am i supposed to torque the wheels accurately using my wrench when the wheels just start to slip, even overcoming the brake pedal pressure?!

And that aside - if i look at the specs of the gun used; it was a milwaukee ONEFHIWF34 - which has a 1627NM of fastening torque, and nut busting torque of 2034NM.

If the wheel nut is being tightened at max torque output of the gun, for a few seconds, i guess the wheel nuts were tightened to at least 360NM, maybe well over - but i don't understand at the moment how to calculate that and how torque values on these impact guns correlate to impact range measured in minutes.

i was going to get the gun they used because it's the 'onekey' range which allows you to set custom settings for the tool via an app, to presumably allow you to set it for a desired tightening torque value (though again i'm not sure how that is possible if you have to first work out how long you have the gun engaged for).

so anyway bottom line...........what methods do you guys use to torque your wheels, and how?

The team told me they use the gun because its easy and time saving, obviously in a race situation it'd be impracticle to get a torque wrench out every time - so i'm now trying to figure out how to use a milwaukee impact wrench and ensure i'm not overtightening the wheel........

I have a 3/4" Milwaukee Impact and will initially torque with that and then check with my torque wrench. I have yet to see nut move much if at all when I check with my torque wrench. I'll mark the nut and the wheel to visually see if there has been any movement. I haven't seen the nut move from the initial mark. I'll then use the impact wrench to take the nuts off.

I just hit it hard with 18v 1/2 drive impact gun (mine's a Ridgid). Then I mark the wheels and check after each session.

Remember to never torque the wheel or hit with a 'gun when hot. Always do that cold.

Like Charley, I use a big 3/4 drive torque wrench: Mountain 16600 3/4" Drive Click Style Torque Wrench - 100-600 ft-lbs/b>

It will help with someone on the brake but it is not necessary. One person can do this.

I think it would be best to use a breaker bar to remove the wheel nuts, but I am lazy so I use a 1/2 impact with 1/2 to 3/4 adapter.

i dont understand why i found it an impossible task then.

as i say, the main reason i couldn't use the torque wrench was because the wheel itself was rotating - even with my mate pushing down on brake pedal to the max.

maybe the garage floor was a bit too slippery, it was a lot smoother than the pitlane/track surface.

i already have all the gear, a breaker bar and massive industrial torque wrench. As i say, i couldn't use either because it was just turning the whole wheel when i tried to torque to the right level.

the brakes were absolutely working as they should be so i dont think its because we weren't pressing hard enough.

So how do you do it on your own then as 1 person, if you have no one to push the brake?

@rojid, tell your friend to step in the brake harder. My wife can generate enough force so he should be able to do it also. When I am solo at the track I usually ask someone at the track if they would like to jump in the car to help me and there is never a shortage of volunteers willing to help. 🙂

@rojid Something does not sound right. Maybe your torque wrench is fouled-up and trying to over-torque the wheel nuts.

When I do this by myself, I just roll the car backwards a little while holding onto the wrench. Or if the bodywork is off the car, then I put my foot on the tire. It does not take a special effort because my wrench is over one meter long.

I'm with David - I routinely torque them alone either using a chock on the ground or just holding the tire with my foot/knee/etc.

@charleyhradicalsportscarregistry-com

it is reversable yup.

i just gave it a go with my torque wrench and it was fine, though i had to use my ratchet clamp spreader thing to hold the brake almost all the way in. Curious to know how some of you are doing it simply by holding the car with your foot whilst pushing down on a giant torque wrench, but anyway. panic over.

i think it was a combination of very slippy garage floor/mate not pushing brake to absolute max/using a borrowed ordinary and shortish torque wrench which is nothing like the norbar 4R i've got.

i guess race teams who are using the electric impact guns are torquing up to a range somewhere between 350-450, holding the gun on a high setting for a few seconds. I suppose i could do the same with my milwaukee gun which has 3 settings, 0-475Nm being the first setting. But how long i'm supposed to leave it on for, and how to calculate that, no idea, i could experiment i suppose - guess i'll just stick to using the wrench.

@rojid .. I'm not sure it's clear which torque wrench you were using. You mention you have a Norbar 4R above, but also mention you were borrowing an 'ordinary and shortish torque wrench'?

Assuming it was a Norbar 4R as mentioned, I had a quick look on their website and could not confirm that the wrench is reversible. It pays to be careful as it needs to be both reversible AND able to measure the torque in that direction as well. Some wrenches can be used to undo right handed threads, (so are working in reverse), but DO NOT measure torque in that direction (they work like a simple wrench or breaker bar)

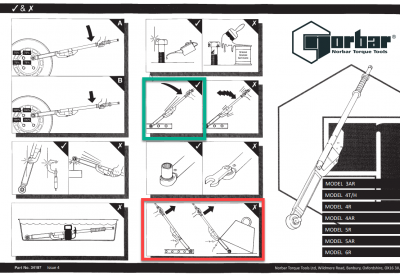

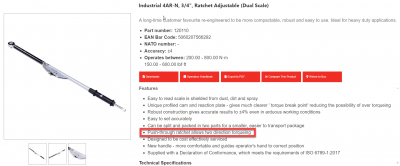

I looked on the Norbar website and found that the 4R range had recently been upgraded to cater for 'two direction torqueing' ... the previous model could not be used in reverse at all.... see picture below

... I think what this is trying to show is that the wrench can only be loaded as per the green box I have marked, and not in the direction as shown in the left hand side of the red box at the bottom.... so it could not be reversed unless you could switch your socket (and the 3/4" drive stub) to the other side of the wrench head... the obsolete model did not have that function... while their new 'upgraded' range has exactly that facility, so you must have that one....

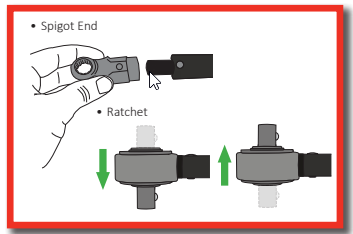

Here's the new specification - it mentions the new 'push-through ratchet allows two direction torqueing' so if this is the one you have you will be OK.

Maybe you could confirm you have the newer version?... but also conform that the 'ordinary and shortish' wrench you might have been using when you had trouble at the track was also a reversible type wrench.... MOST TORQUE WRENCHES ARE NOT REVERSIBLE....

@rojid ... sorry another question and a comment to try and help....

While trying to loosen the wheel nuts, were you or the person using the torque wrench pushing down on the wrench handle, or pulling up?

It makes a difference because when you are pushing down you are effectively adding weight to that wheel, and this goes some way to making it less likely to spin on the floor/ground. If you are lifting or pulling up on the wrench or breaker bar you are taking the weight off the wheel and that can make it a lot harder to do without the wheel rotating.

I had this learning experience when I first got my car. I have an epoxy floor in my garage and it is pretty smooth. I could not get the wheel nuts to come loose, even with my wife pushing on the brake as hard as she could.... after thinking about it, I simply moved around to the other side of the wheel (so then I was pushing the 750mm long breaker bar I was using down towards the ground and it came loose easily, without the tyre breaking traction o the floor.... I now always do it this way...

That's a big part of the reason that a longer wrench or breaker bar will be better in most cases... the same effort on the end of the wrench gives proportionally more torque with a longer bar (and with proportionally less tangential force transferred into the object being undone or done up.)

On your questions about the relationship of torque setting and 'time' when using your Milwaukee impact gun - from a theoretical point of view there is no relationship between torque and time. Torque is a measure of the 'twisting force' applied to an object, and time has no bearing on that.

Having said that, these are called 'impact guns' and not 'torque guns' for a reason. They don't really apply a constant torque (like your manual wrench does) they rely on the gun giving an 'impulse' to the socket/nut. A pure impulse is a linear force applied over a certain time, but in the case of an impact gun, its a 'torque' applied over a certain time. Each time the impact gun gives an 'impulse' to the nut it will get tighter until nut is tight enough to overcome anymore impulses.

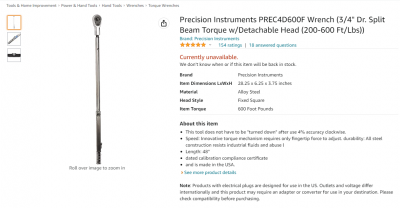

I use both a torque wrench (shown below) and a 3/4" Milwaukee 'one-key' impact gun.... but I never torque the wheel nuts up using the impact gun only. I do the wheel nuts up with the impact gun. but only until the wheel is 'snugged' into place (maybe one or two 'impulses' on the lowest and slowest setting)... then I tighten them to 265ft/lbs (360N.m) using the wrench below.

When undoing the wheel nuts and with hot wheels (soon after racing) I first 'crack them' with a breaker bar to start to move them, and then take them off with the impact gun. I have had trouble getting them to move while hot without using the breaker bar first.

If the wheels are cold (when back at home or after a long break off track) the impact gun works fine.

Note - it took me a long time to find a torque wrench that could be used in reverse - hence my previous post above.

The other point made by others is absolutely critical - the wheel nuts torque up differently when the wheels are hot. I always torque them up when cold, and then mark them to make keeping an eye on them easier...

thanks for the detailed response - yup it is definitely reversible.

I was borrowing someone elses wrench (the only other radical owner on the day) - i got to track and realised i'd left the little 3/4" coupler piece so i couldn't attach the Socket to my own Norbar wrench.

to answer your question - yes i checked with both Sykes Pickavant and Norbar (Sykes resell Norbar products) - for their industrial range, if its a push-through square head then they they do torque in both directions.

Indeed as you've shown the 4R was updated - it isn't clear from any site description that the previous model is reversible which is why i called up Norbar and asked when i bought mine.

And yes I do push down - it's the only way the wrench can be used, the body of the wrench "Breaks back" and collapses in the middle when the torque is reached, it doesn't 'break' the other way. It doesn't require much effort at all, i think i struggled on the day as i say, because i was using a much shorter click wrench which i had to borrow.

Yup i've settled on your approach also - my milwaukee gun FMTIW2F12 has a 4th setting which is for fastening up nuts to a low torque level (47NM in the manual) and then i use the wrench for the rest.

I'm sure using the gun on it's 1st setting and leaving it on for a few seconds should be torquing the wheels up to >360NM, as the teams do. I wonder what the safe tolerance is with the wheel nut, how much is too tight etc. clearly a range is acceptable.

It would be a lot easier to do this then faff about with a large torque wrench each time - then again i guess i'm only doing it once on a track day so it's not a big deal!