F1 Style Halo / Center protection

@tmpoquette As a new owner, I have no experience with the cost of parts on the SR3. I completely agree that $1100 for a mild steel upright that only has a 40 hour life on it is rather ridiculous. I hope that the cast version turns out to be a little bit more affordable. Thanks.

Jay

Posted by: @tmpoquetteAlmost everything Radical price wise is crazy to me. Seems like they have a 3x rule.

I am not apologizing for Radical's high price parts, but this is prevalent in the race car business because the volume is so low, which means that if they do not make a lot of money on parts then they cannot afford to hire competent staff to produce the cars and parts.

A brand new Hayabusa motorcycle costs less than a new 1500 RPE engine. My 2020 GMC dual rear wheel truck fully loaded Denali trim cost $83k new -- far less than a new Radical SR3.

Racing is expensive. The least expensive high performance car is a Van Dieman open wheel F2000 which is also very fun to drive, however it is not a great track day car because you can get run over and squashed by a 4000 pound car that does not see you. Another low cost option is Spec Racer Ford gen 3, however it is not nearly as capable or as fun to drive as an SR3. The SCCA FE2 is just as capable as an SR3, is more fun to drive, and far less expensive so if you really want to have your cake and eat it too, then I would suggest racing school to get your full competition license, and then competing in FE2 with SCCA. However, it is not a perfect world because an SCCA race weeking includes only a 25 minute sprint on Saturday and a 35 minute sprint on Sunday. Often both races are yellow flagged, so you can spend a lot of time and travel cost for nothing on some SCCA race events. I am going back to Radical Cup racing this year because the race series is so much better than SCCA.

I think bike engines should be phased out of race cars, replaced with car engines like the Honda type R and Mazda MZR, and that the chassis and bodywork should be upgraded from steel and fiberglass to a monocoque carbon fiber chassis to save weight while increasing rigidity, strength, and safety. An example are the current cars produced by Tatuus. The car cost and parts will still be expensive, but the service intervals for the engine will be much longer than a bike engine.

Update on the temperature strips. I purchased the temp strips from Pegasus.com who I think has the best price on these, $18 for 10 strips:

| RP-TEMP-230 | Racetech 8-Temperature Strips, 160-230 F (71-110 C) 10-pk |

These are irreversable marking, meaning that they record the peak temperature reached. I also have a couple of these which were stuck on the engine head when I got it back from Spring Mountain. There is always something new to learn and do better.

Posted by: @davidfUpdate on the temperature strips. I purchased the temp strips from Pegasus.com who I think has the best price on these, $18 for 10 strips:

RP-TEMP-230 Racetech 8-Temperature Strips, 160-230 F (71-110 C) 10-pk

Hi David, ... so to be clear these strips (in that temperature range) are the ones you suggest using on the uprights bearing carrier? I already use these type of strips in a number of applications around the car (mainly the GDU and Cylinder Head of the engine) and would like to understand what strips to install on my uprights... and maybe you could also indicate what 'normal ' temps loo like...?

Has anyone heard anymore about the 'cast uprights'? I'm hearing that Radical may have decided to either put these on their 'go slow' list... or maybe not proceed with them at all. I'd like to know as I have an RSX here with standard uprights, and my new XX has billet uprights... and after a recent crash in my RSX I'm having to replace some of my 'spares' which have had to be installed on the RSX to replace those damaged.... not sure which to purchase to put back on the shelf - billet or standard...

For what it's worth, after having my first crash, I totally agree that the billet uprights will come at the expense of higher risk of chassis damage...

Hi Rod,

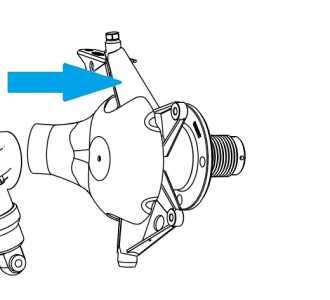

Yes, these are what I have on my SR3 uprights -- Temp range B 71 to 110 C. I have reached 104 C on my uprights and beginning to reach 110C, including a new one, so I guess that is the normal high temperature. I think the next temperature range may be needed -- 116 to 151 C. I placed them on the upper arm (see photo)

because it is easy to see and access, but I am not certain whether this is the ideal location. If and when I can confirm, I will report back.

Again, this temperature strip hack is used to determine if the the bearing and therefore entire steel upright should be replaced, avoiding excessive parts replacement cost. The user manual calls for 6000km lifing (I believe). There is a safety issue here because the welded seams of the upright will eventually split, and safety should be the primary concern (over replacement cost). I wipe down my uprights during prep and inspect them at the track for any indication of imminent failure. The goal is to stretch the lifing a little bit, but not so much that it poses a safety risk. I will probably replace at 10km or when the temperature has climbed to 120C.

@davidf - Thanks David - that will be a very good head start once I get my car back together.

My only concern with what you have shown is that the temp strip will likely be impacted by a lot of radiant heat off the brake disc (even if its conducted through the steel part of the upright you have shown with an arrow). When I was imagining what you had described in previous posts, I was picturing the temp strip fitted to the actual housing that the wheel bearings are inside. I think the only issue with this is how easily it could be seen... but this is probably something I would only look at or check in between events anyway...

Because my RSX is apart at the moment (and my XX has billet uprights which are totally different) I can't see exactly how much room there would be with everything installed...

Using the parts off my car I've tried to see if that's possible - see photo... There is no caliper or rotor assembly here... but maybe a temp strip could be fitted as highlighted in the red square, on the opposite side of the housing to the brake caliper (near that lug that houses the wheel speed sensor)? The benefit would be it's not near the 'hot face' of the brake rotor plus its down inside the cooling duct area, so hopefully would show the temperature of the housing directly where the bearings are mounted... what do you think?... or maybe with everything fitted it would still be hard to see...??