Normal running temperatures

These thermostats are more diverter valves that full flow in diverted or through flow mods.ie only flows through the cooler radiator when oil reaches desired temperature.

They don’t function as per dead head water thermostats .ie only flow when open.

AN 10 in AN 12 out as per factory .

@rlm-dan - G'day Dan,

I've just installed a water thermostat and the bleed nipple under the head as you suggested. I've put in an AN-6 fitting and will run the -6 hose down to the radiator 'aluminium tube'... the question is which one should the fitting be welded into?

I thought it would be more obvious, but I'm afraid I don't understand enough about which way the water circulates when the thermostat is closed...

Should the hose from the bleed nipple go onto the straight tube that is connected to the coolant pump or the curved aluminium tube that returns the coolant back to the swirl pot?

I also noted that there was a small hole (what I would call a bleed hole) in the thermostat itself (probably 2mm diameter?). Is that normal?

@rjbender Hi Rod,

Glad you are making progress.

The fitting needs to go into the bottom pipe that goes from the water pump to the fitting on the cylinder barrel. Attached is a picture. (Personally I would have gone further up the pipe, towards the engine, but that would just be to keep things neat).

With this installed the water will go into the cylinder barrel, travel through the cylinder head and then out of the bleed that you have now fitted, back down and then into that bottom pipe. You essentially end up with a mini circuit there until the thermostat opens - which is about 82°C.

The bleed hole in the thermostat is normal and should be there.

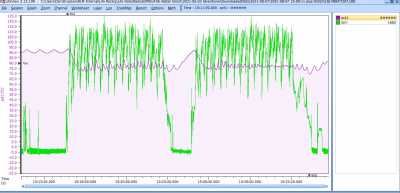

It is important that when you are warming the car up at the start of each day/event that you let the water get above the 82° and the thermostat open so that you do get some warmth in the entire coolant system - which should happen naturally anyway with trying to get some oil temp. You will also note a 'wave' your water temp trace on track as the thermostat opens and closes.

Just an aside note you will not get the normal swirl of water in the swirl pot until the stat has opened, this has caught a few people out thinking they had a problem forgetting about it!

@parsonsj sorry John, I have only just noted this!

We have used the oil thermostats like John W has here in a number of 7 style cars and they are great, they take a lot of the trouble out of worrying about tape on the radiator and also help get everything up to temperature quicker.

We have yet to try one on a Radical but plan to in the near future, the PR6's are so over cooled for UK use that when it rains we completely blank the oil radiator and still struggle to get up to a decent temperature, as the back of the rad get soaked from water ingress.

I understand on the keeping the oil above 100° but to be honest it is not something that we have bothered with. With not wanted to run above 110° it leaves little room if someone has slightly blanked the radiator off too much and we also find that on some engines the oil pressure can be a little lower than expected so we get nervous of the oil pressure when over 100°. I guess the oil is changed so frequently in a Radical that it does not matter if there is a small amount of water ingress? I certainly could not say that we have seen less or more wear to bearings and internals on engines that are consistently ran above or below that point.

@rlm-dan I've indirectly put in a thermostat in mine -- I'm using ECT as a variable to turn on (and off) the coolant pump and fan. However, it still takes a lap or so before the ECU allows full throttle and redline due to safety programming I've put in the tune. I'm currently redesigning the coolant path between the radiators on my now-RPX SR8. If I were to put in a t-stat, where in the path should it go?

@rlm-dan - Champion Dan... looks like I was on the right track.. see pictures below of what I've done so far. I'll run -6 hose between the fittings shown in the pictures once I've got the new engine plumbed in.

All you comments are noted... including the hint about not expecting to see the swirl pot 'active' during initial warm-up.

Up until now, I've actually been putting a 240 volt, 600 watt immersion heater ($11 on ebay!!) directly into the swirl pot before I even start the car, and made a 'patch cable' that allows me to force the coolant pump on to move the warm water into the engine every 5 minutes.... takes about 40 minutes to get the water temp from ~10 degC to 40 degC, including warming the entire engine block, head, radiator contents, etc. This is done at the same time the heat pad on the dry sump tank is in use, which talkes the oil temp to 50 degC in about the same time - with both heaters on (running off my Honda generator) this really speeds up final warm up once the engine is running.

I've also just installed a Mishimoto 82 degC oil thermostat - see pictures below.

So now I should be able to warm up the engine (prior to starting it) with the water immersion heater and the dry sump heaty pad.... then once I start the car the thermostats on both the water side and the oil side should allow the engine to heat up much more quickly, so I won't be using so much of my precious engine run time on sitting in the pits just warming things up.

... This problem is larger for people like me who tend to compete in much shorter duration events/races. During the hillclimbs I do occasionally, each run is normally less than 60 seconds! (6 runs in an event)... while even the Sprint Races that I mostly use the car for a only 8 -10 minutes in duration (15 total from leaving the pits to returning), with 5 or 6 of these held over 2 days. So when you look back after each weekend... there might be around hour or less of 'track/race time' and maybe close to 3 or 4 hours of 'warming up' (assuming no thermostats and immersion heater, etc)

Your help has been very much appreciated.

@parsonsj Hi John,

Unfortunately I don't think it is something that you can do with the V8 engine, I don't have one here to check currently, but as Radical do a custom fitting to join the cylinder head water fittings an OEM Suzuki thermostat will not fit - plus I guess you would have to run two which would be an odd set up?

Do you have the option to control water pump speed? Maybe constantly running slowly to start with would be better than an on/off?

@rjbender Hi Rod,

All looks good!

I would be interested in your feedback on the oil thermostat once you have had chance to run it.

That's a good idea on the immersion water heater, especially for the price! Hopefully that will still work for you with the thermostat in as the water obviously won't flowing anywhere near as well.

@rlm-dan Thanks for that idea. My water pump is powered via an ECUMaster PMU16 and can be controlled via an override switch or by the ECU, all managed via CAN bus messaging. It might be a fun project to add a PWM / PID control mode and see how various speed/feedback strategies affect coolant temp.

I could also snag an inline 1 1/4" thermostat and fit it inline between the cylinder heads the swirl pot.

EDIT: I messed around with my ECU and PMU16 and got this idea working. The water pump will start slowly around 60*C and get to full speed at 90*C. This should help the engine warm up more quickly, and then the oil and trans fluid temps will follow.

@rlm-dan - G’day Dan, A quick update on the water thermostat and how it works with the direct immersion heater.

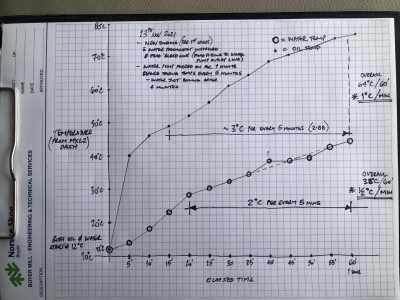

Today I added the new oil and coolant after finishing installing the new engine. After that I turned on the dry sump heat pad (Wolverine 250 watt) and put the $10 ebay immersion heater (600 watt I think) directly into the swirl pot.

I ran a test over 60 minutes, checking the temperatures every 5 minutes, and forcing the coolant pump on for the last minute of every 5 minute interval to circulate the coolant from the swirl pot into the engine. (The swirl pot would boil after about 5 minutes if I didn’t force the pump on the move the hot water into the block/head). After 20 minutes of the test you could feel heat in the block, head and radiator - proving there was water circulating through the system enough to heat everything up.

On the oil side, as expected the oil heater just heats what’s in the dry sump tank and the dry sump itself barely changed temperature as no oil circulates until I start the engine.

shown below is what I measured.

To summarise the results over an hour…. oil temp in the dry sump tank rises by 1 degree C per minute, while coolant temp rises by 1/2 degree C per minute.

So a 1 hour warmup before the first start of each day will be great!